Volume 13 - Year 2025 - Pages 15-25

DOI: 10.11159/ijtan.2025.002

PVDF-Based Electronic Skin: Mimicking Life for Enhanced Human-Machine Interfaces

Yatin Kohli

SRM Institute of Science and Technology, Department of Mechanical Engineering (Robotics)

Kattankulathur, Chennai, Tamil Nadu, India- 603203

yk9618@srmist.edu.in

Abstract - Electronic skin (e-skin)- elastic, flexible materials that replicate the sensory capabilities of human skin- has emerged as a transformative field of research. This review paper critically examines the role of Polyvinylidene fluoride (PVDF) and its composites in enabling next-generation e-skin sensors. Unlike prior surveys, this review (i)complies a unified fabrication checklist for PVDF/MoS2 / BaTiO3 – based devices, (ii)presents a normalized benchmark table for recent PVDF and PVDF-composite e-skins, and (iii)introduces a standardize nomenclature of device parameters. We analyze how advanced fillers (e.g., MoS2, BaTiO3) and fabrication protocols improve piezoelectric, piezoresistive, and durability metrics, while also mapping PVDF-based e-skins to Internet of Things (IOT) applications. Key challenges- such a large-scale fabrication, long-term stability, and signal processing- are critically discussed, and future directions including AI-driven adaptive sensing, self-healing materials, and biocompatible integration are highlighted. The study positions PVDF nanocomposites as a central pillar in the advancement of robust, self-powered, and IoT-ready e-skin systems.

Keywords: E-Skin, PVDF, Nanocomposite, IOT, Robotics.

© Copyright 2025 Authors - This is an Open Access article published under the Creative Commons Attribution License terms. Unrestricted use, distribution, and reproduction in any medium are permitted, provided the original work is properly cited.

Date Received: 2025-05-26

Date Revised: 2025-09-25

Date Accepted: 2025-10-06

Date Published:2025-10-14

1. Introduction

The human skin, an astonishing feat of natural engineering, has inspired the creation of electronic skin (e-skin)—flexible[1], elastic materials designed to duplicate its sensory capabilities for advanced human-machine interaction. Biological skin features networks of mechanoreceptors, thermoreceptors, and nociceptors, which provide complex awareness of touch[2], temperature, and pain[3], setting a benchmark for e-skin innovation.

This review article focuses on the crucial role of polyvinylidene fluoride (PVDF) nanocomposites in advancing e-skin technology, particularly their use in fabricating durable, sensitive[4], and flexible piezoelectric sensors. Unlike earlier reviews that broadly covered stretchable electronics, this work concentrates on PVDF and PVDF-composite e-skins, presenting fabrication pathways, normalized device-level comparisons, and clear nomenclature to guide reproducibility[5].

Nomenclature Box

|

E-Skin |

Electronic Skin |

|

PVDF |

Polyvinylidene |

|

MoS2 |

Molybdenum Disulfide |

|

BaTiO3 |

Barium Titanate |

|

PDMS |

Polydimethylsiloxane |

|

PET |

Polyethylene Terephthalate |

|

PI |

Polyimide |

|

PU |

Polyurethane |

|

IOT |

Internet of Things |

|

Eco-Flex |

Silicone Rubber |

|

Piezoelectricity |

Electric charge generated by mechanical stress |

|

Piezo resistivity |

Resistance changes due to mechanical strain |

|

LOD |

Limit of Detection |

1.1 Introduction to Work Done

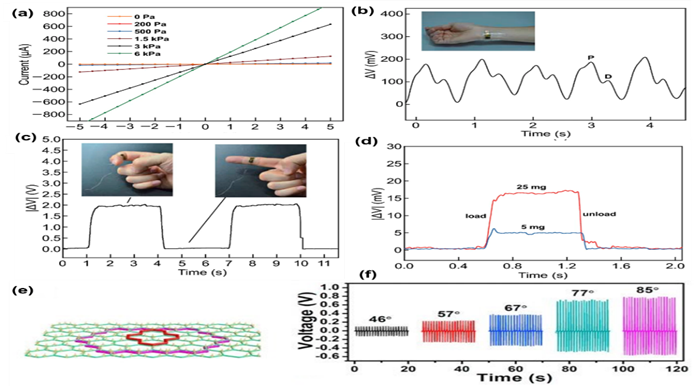

Table 1. provides a comparative overview of the major flexible sensing mechanisms including piezoresistive, capacitive, piezoelectric, triboelectric, and optical approaches. Each mechanism is summarized in terms of the materials typically employed, their key performance advantages, and the most common applications in wearable and electronic skin devices. This comparison highlights how PVDF-based piezoelectric sensors stand out for their self-powered capability and wide dynamic range, making them highly suitable for real-time physiological monitoring.

Table 1. Comparative table of Flexible Sensing Technologies

|

Sensing Mechanism |

Material Used |

Key Advantages |

Typical Application |

|

Piezoresistive |

CNTs[6], Graphene[7], Conductive Polymers |

High sensitivity, Simple fabrication, Low cost |

Strain, Pressure, and Motion sensing[8] |

|

Capacitive |

Elastomers, PDMS[9] with conductive layers |

Excellent stability, High sensitivity to pressure, less affected by temperature changes |

Pressure sensing, Tactile sensing, Proximity detection |

|

Piezoelectric |

PVDF, ZnO nanowires[10] |

Self-powered, High dynamic range |

Vibration, Pulse monitoring and Acoustic sensing[11] |

|

Triboelectric |

Various polymers (e.g. PET, Kapton) |

High efficiency for converting mechanical energy, Self-powered, Versatile |

Pressure sensing, Motion detection[12], Energy harvesting |

|

Optical |

Optical fibers, Photodiodes |

Immunity to electromagnetic interference, Good for in vivo sensing |

Blood oxygen saturation and Heart rate monitoring[13] |

1.1.1 Overview

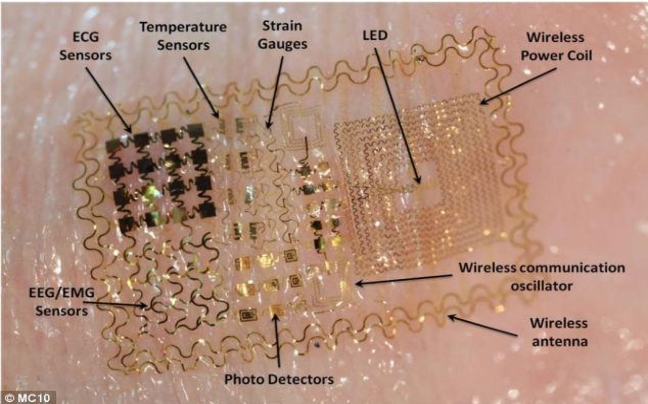

Electronic skin (e-skin) refers to flexible, stretchable electronic systems designed to replicate the sensory and responsive functions of human skin[14]. By integrating sensors and actuators onto flexible substrates[15], e-skin can detect external stimuli and respond in ways similar to physiological reactions[16]. This technology has transformative potential across fields like advanced prosthetics, robotics, wearable technology[17], and healthcare monitoring, enabling intuitive human-computer interaction and continuous, non-invasive health tracking[18]. With applications ranging from sensitive robotic touch to environmental sensing[19] and personalized medical diagnostics, e-skin bridges the gap between humans and machines[20]. The use of PVDF nanocomposites combined with IoT technologies promises a future of seamless, intelligent connectivity[21], making electronic systems an almost natural extension of the human body[22].

1.1.2 Potential Applications

PVDF nanocomposite-based electronic skin, with its inherent flexibility, sensitivity, and adaptability, finds a broad spectrum[23] of potential applications across various industries, each poised for significant transformation[24].

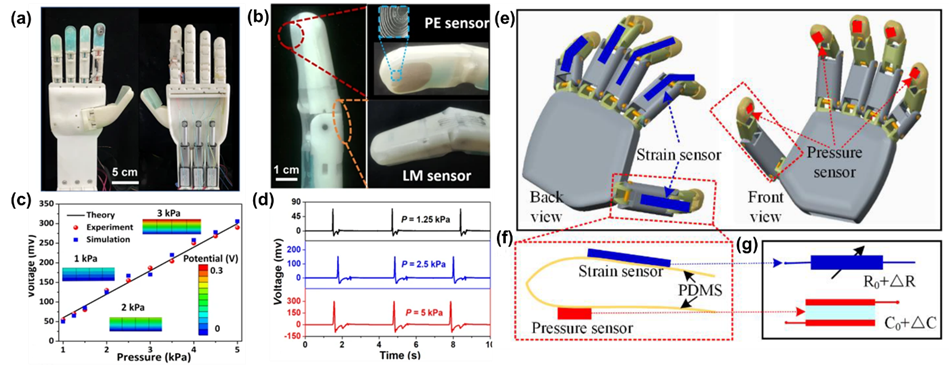

- Robotics: E-skin enhances robotic systems by providing them with a sense of touch[25], enabling safer and more precise interactions with their surroundings. This allows robots to handle delicate objects, overcome obstacles, and interact intuitively with humans, supporting advanced tasks including surface recognition, soft robotics, and adaptive control.

- Tactile Sensing: E-skin enhances robotic systems by enabling them to sense tactile data like temperature, vibration, and pressure, allowing more accurate and responsive interactions[26] with people and objects.

- E-skin for Object Manipulation and Robotics: The integration of tactile feedback from e-skin significantly enhances the dexterity and precision with which robots can handle objects[27]. By sensing the forces applied during grasping, robots can intelligently adapt their grip, which allows them to firmly and securely hold objects of widely varying sizes, textures, and shapes[28], reducing the risk of slippage or damage.

- E-skin for Prosthetic Devices: E-skin integrated into prosthetics and wearable devices enhances sensory feedback, allowing users to experience sensations like natural touch[29]. In healthcare, it enables continuous vital sign monitoring, improves surgical precision through real-time tactile feedback[28], and supports rehabilitation by providing responsive, adaptive feedback[30].

- Human-Machine Interfaces: E-skin is a critical enabler for the development of highly advanced human-machine interfaces that respond intuitively to touch and gestures. By embedding tactile sensors into interactive surfaces, e-skin can dramatically enhance[31] usability and unlock novel interaction modalities, moving beyond simple button presses to more nuanced and expressive gestural controls.

- Environmental Monitoring: E-skin can be deployed in sophisticated environmental monitoring systems to accurately detect minute changes in pressure, humidity, and temperature[32]. When integrated into smart surfaces, tactile sensors facilitate real-time monitoring of critical infrastructure and sensitive ecosystems, providing early warnings for potential issues[3].

- Industrial Automation and Quality Control: In industrial settings, e-skin serves as a vital tactile sensor for highly precise robots and automation systems[33]. The tactile feedback helps to ensure consistent product quality, facilitates the immediate detection of defects, and allows for the continuous optimization of complex manufacturing processes[34].

- Smart Textiles and Fabrics: Integrating e-skin into smart textiles enables interactive clothing and advanced wearable health monitors[35] that can track body movements, posture, and provide real-time feedback for rehabilitation or sports training[34].

1.1.3 Advantages

The inherent design and material properties of e-skin confer several compelling advantages, making it an indispensable tool for future technological advancements.

- Sensitivity: E-skin sensors can detect a wide array of physical stimuli, including delicate touch, varying levels of pressure, temperature fluctuations, and even subtle changes in humidity[36]. This makes them incredibly versatile and adaptable for deployment in diverse and complex environments.

- Durability: Despite their thin and flexible form factor, e-skin designs prioritize robustness and are engineered to withstand significant wear and tear[37]. This durability is a critical differentiator compared to more rigid and fragile traditional sensors.

- Biocompatibility: Specific varieties of electronic skin are meticulously designed for biocompatibility, allowing safe utilization in medical applications[38] without provoking unpleasant reactions or inflicting harm on the human body. This facilitates the development of implanted devices and prolonged wearable health monitors.

- Real-time Feedback: The capacity of e-skin to deliver instantaneous feedback is revolutionary. This quick reaction capability is vital for applications where instantaneous information is required, such as enabling prosthetic limbs to "feel" their surroundings and react intuitively[21].

- Customization: Electronic skin technologies offer a high degree of customization and can be precisely tailored to suit vastly different needs.

- Energy Efficiency: Many electronic skin technologies are designed with energy efficiency as a core principle[39], often requiring minimal power consumption for continuous operation.

- Integration: E-skin is engineered for seamless integration into existing systems and device architectures[40], positioning it as a cost-effective and efficient solution for upgrading conventional devices.

- Remote Monitoring: The inherent connectivity potential of electronic skin enables robust remote monitoring of various parameters[41], including vital signs in healthcare or environmental conditions. Remote monitoring enhances safety, convenience, and provides crucial data for proactive decision-making.

- Innovation: The ongoing development and refinement of electronic skin technology are continuously opening new possibilities and driving innovation across diverse fields, fostering advancements in healthcare, robotics, and materials science[42].

2. Background Material

PVDF-based electronic skin relies on the piezoelectric properties of PVDF, which convert mechanical stress into electrical signals. This capability enables sensitive detection of touch, pressure, and other stimuli, making it ideal for applications in sensing, actuation, and energy harvesting across various industries. Its flexibility and lightweight nature allow seamless integration onto curved surfaces, mimicking human skin for advanced robotic and wearable applications. The material’s robustness and responsiveness make it suitable for both dynamic and static sensing environments.

2.1 Conceptual Overview

By integrating flexible e-skin with IoT, real-time data collection, remote monitoring, and intelligent control become possible. This combination enhances human-robot interaction, enables continuous health monitoring, and supports automation, creating smarter and more responsive systems. IoT connectivity allows large-scale deployment of e-skin-enabled devices, facilitating data-driven decision-making and predictive maintenance. Additionally, this synergy opens opportunities for personalized healthcare, adaptive robotics, and interactive smart environments.

2.1.1 Theory Used

The foundational principles underpinning the functionality of PVDF-based electronic skin are rooted in advanced material science and engineering concepts, primarily focusing on piezoelectricity and its synergistic integration with e-skin design and the Internet of Things (IoT).

- Piezoelectricity: Piezoelectricity, present in materials such as PVDF, facilitates the creation of electric charges upon the application of mechanical stress, and conversely. This feature renders PVDF optimal for e-skin applications[43], as it effectively transforms touch or pressure into electrical signals, facilitating applications in sensing, energy harvesting, and precise actuation across diverse industries.

- E-Skin: Electronic skin (e-skin) simulates the sensory properties of human skin utilizing flexible sensors and actuators to sense inputs like pressure, temperature, and humidity. It improves human-robot interaction for safer, more accurate operations[44] and revolutionizes healthcare through continuous, real-time health monitoring and tailored feedback, facilitating superior health management[45].

- Internet of Things (IoT): The Internet of Things (IoT) interlinks various physical objects equipped with sensors and software, facilitating remote monitoring, control, and data sharing to enhance efficiency and convenience[46]. The collection of real-time data via IoT improves decision-making and automation in various industries, yet it also presents significant security and privacy challenges that necessitate robust safeguards[47].

3. Fabrication of E-skin

The production of diverse e-skin devices, especially those utilizing PVDF, adheres to a systematic and rigorous general protocol. This procedure incorporates meticulous material preparation, deliberate mixing, and systematic assembly to attain flexible, sensitive, and resilient properties vital for sophisticated electronic skin. The process is consistent across many e-skin types, with differences mainly in the active ingredients and their concentrations.

3.1 General Fabrication Procedure

The fabrication process for each e-skin device type generally follows these steps[48]:

- Initial Mixture Preparation: This phase commences with the precise measurement of selected active components, including Polyvinylidene Fluoride (PVDF), Molybdenum Disulphide (MoS2), and Barium Titanite (BaTiO3), chosen for their distinct contributions to the qualities of the e-skin. The components are carefully blended in a container to guarantee uniform distribution. Two components of a biocompatible binding polymer (e.g., Eco-Flex cure silicone rubber Part A and Part B) are combined in a precise ratio. The produced polymer mixture is subsequently incorporated into the active components within the container, and the amalgamation is meticulously agitated. This procedure is crucial for maintaining uniform material qualities and ensuring the active components are evenly dispersed inside the flexible polymer matrix, which contributes to the e-skin's comfort and longevity.

- Curing/Drying: After thorough mixing, the solution-filled container is typically left overnight. This allows the binding polymer to cure, transforming the liquid mixture into a solid yet highly flexible and durable material. The overnight drying also ensures optimal mechanical properties and structural integrity.

- Device Formation: Once the material has fully dried and cured, a precisely cut piece of the prepared material, with a specific area (e.g., a square centimetre), forms the core of the e-skin sensor device. This piece is then strategically sandwiched between two pieces of copper tape. These copper tapes serve as crucial electrical contacts or electrodes, facilitating the capture of electrical signals generated by the piezoelectric or piezoresistive effects within the e-skin material when subjected to mechanical stimuli. This selective copper tape electrode placement is a key engineering consideration for reliable sensor systems.

- Encapsulation: In many fabrication protocols, an optional yet important additional layer of the mixed binding polymer is poured over the prepared device containing the copper tape. This serves as a final encapsulation step, providing further protection to the active material and electrical contacts from environmental degradation, mechanical damage, and moisture. This resilient encapsulation highlights the engineering challenges and creative ideas for producing dependable and robust sensor systems, contributing to their long-term stability and performance.

3.2 Specific Material Preparations

While the general procedure remained consistent, the specific active materials and their combinations varied to optimize properties for diverse applications:

- MoS2 Devices: E-skin devices were prepared primarily using MoS2 as the active material.

- BaTiO3 Devices: E-skin devices were fabricated using BaTiO3 as the active material.

- PVDF Devices: E-skin devices were made with PVDF as the active material. Additionally, devices with different proportions of PVDF were also prepared to examine concentration-dependent effects.

- MoS2+PVDF Devices: This involved combining MoS2 and PVDF as active materials. Variations in the amount of MoS2 were explored while keeping the PVDF content constant to assess their synergistic effects.

- BaTiO3+PVDF Devices: E-skin devices were created using a mixture of BaTiO3 and PVDF. Different concentrations of BaTiO3 were investigated while maintaining a consistent amount of PVDF.

- BaTiO3+MoS2 Devices: E-skin devices were constructed with a mix of BaTiO3 and MoS2[49]. The procedure comprised preparing devices with various quantities of BaTiO3 while keeping the MoS2 content fixed.

- MoS2+BaTiO3+PVDF Devices: This involved a more complex ternary mixture of MoS2, BaTiO3, and PVDF as the active materials, allowing for the optimization of multiple properties simultaneously.

This multi-step process is precisely tailored for different material combinations and concentrations, with each variation designed to optimize properties such as piezo resistivity (the alteration in electrical resistance due to mechanical strain) and surface characteristics (e.g., hydrophilicity/hydrophobicity), which are essential for the optimal performance of sensitive and flexible electronic skin in its various applications.

To achieve reliable and high-performance e-skin devices, the choice of materials and fabrication methods plays a critical role. Table 2 summarizes the commonly used substrates, conductive traces, encapsulation layers, and active components, along with the key fabrication techniques adopted for each category.

Table 2. Summary of Materials and Fabrication Techniques

|

Component |

Common Materials |

Key Fabrication Techniques |

|

Substrate |

PDMS, Polyimide (PI), Polyurethane (PU), Polyethylene Terephthalate (PET) |

Spin coating, Electrospinning, Spray coating[50] |

|

Conductive Traces |

Liquid metal alloys, silver nanowires[51], CNTs |

Inkjet printing, Screen printing, Lithography, Roll-to-roll processing |

|

Encapsulation |

Parylene, Eco flex, Silicone |

Vapour deposition, Lamination |

|

Active Components |

Silicon nanomembranes, Organic Semiconductors |

Transfer printing, Pick-and-place method |

4. Results and Discussion

This study demonstrates that PVDF nanocomposites enhanced with MoS₂ and BaTiO₃ exhibit superior piezoelectric, piezoresistive, and mechanical properties[52], making them highly suitable for advanced tactile sensing in electronic skin applications. The integration of a flexible Eco-Flex silicone matrix ensures mechanical durability and long-term stability under repeated deformation. These sensors display high sensitivity[53], fast response times, and signal stability across various stimuli, supporting their use in real-time prosthetic and robotic interfaces. Additionally, the seamless integration with IoT frameworks opens avenues for remote monitoring, gesture control, and personalized healthcare. While challenges remain in large-scale manufacturing and advanced signal processing, future developments in AI-driven adaptive sensing and self-powered systems hold promise for fully autonomous, biocompatible, and commercially viable e-skin technologies[54].

Table 3. presents a quantitative comparison of various PVDF-based electronic skin devices, highlighting their key performance metrics such as sensitivity, response time, durability, and output mode. It provides a clear overview of how different material composites and designs influence the sensing capabilities and practical applications of e-skin technologies. This comparison aids in evaluating the suitability of each device for specific real-time monitoring and human-machine interaction scenarios.

Table 3. Quantitative Comparison Table

|

Device Type |

Stimulus |

Range |

Sensitivity |

LOD |

Response |

|

PVDF- MoS2 composite |

Pressure |

0-250 Pa |

314 kPa-1 |

0.5 Pa |

40/60 ms |

|

PVDF-HFP |

Pressure |

0-200 kPa |

0.468 pF/Pa |

0.065 Pa |

0.1mm dielectric layer |

|

PVDF-HFP |

Pressure |

0-200 kPa |

9.51 kPa-1 |

Not specified |

Not specified |

|

PVDF/ZnO/Graphene Hybrid |

Pressure |

0-310 kPa |

3.2 mV/kPa |

Not specified |

Not specified |

|

PVDF- based capacitive sensor |

Pressure |

0-200 kPa |

5.734% kPa-1 |

Not specified |

200ms |

|

Device Type |

Cycles |

Output Mode |

Thickness |

Test Conditions |

|

PVDF- MoS2 composite |

105 cycles |

Piezoelectric |

200µm |

Ambient lab |

|

PVDF-HFP |

Not specified |

Capacitive |

Not specified |

Not specified |

|

PVDF-HFP |

Not specified |

Capacitive |

Not specified |

Not specified |

|

PVDF/ZnO/Graphene Hybrid |

Not specified |

Piezoelectric and Thermoresistive |

80µm |

Not specified |

|

PVDF- based capacitive sensor |

>105 cycles |

Capacitive |

Not specified |

Not specified |

5. Conclusion

This review paper highlights the crucial role of PVDF-based nanocomposites in the evolution of the e-skin technology. By systematically integrating advanced filler such as MoS2 and BaTiO3 into PVDF matrices, researchers have demonstrated remarkable improvements in sensitivity, flexibility, and durability, thereby meeting the stringent requirements of next-generation e-skin devices[55]. Unlike previous surveys, this review contributes three distinct elements: (i) a unified fabrication checklist for PVDF/MoS2/BaTiO3 e-skins, (ii) a normalized benchmark table consolidating device-level performance metrics, and (iii) a standardized nomenclature for key parameters used.

The analysis underscores that PVDF nanocomposite e-skins exhibit fast response/recovery times, robustness across 104-105 cycles, and inherent self-powered operation- making them particularly suited for integration into IoT. Furthermore, the normalized comparison reveals that device performance is highly dependent on filler type, substrate selection, and test conditions, offering valuable guidelines for reproducibility and optimization.

Overall, PVDF-based e-skins represent a significant leap toward intelligent, biocompatible, and energy-efficient human-machine interfaces. The findings of this review provide both a practical roadmap and a reference baseline for researchers aiming to design scalable, robust, and IoT-ready e-skin technologies.

6. Future Scope

The future trajectory of PVDF-based e-skin research is poised to expand across materials, device engineering, and system-level integration. Building upon the fabrication checklist and benchmark data compile in this review, several opportunities emerge:

- Advances Materials: Development of ternary and quaternary PVDF composites (e.g., PVDF/MoS2/BaTiO3/Graphene)[56] will allow researchers to exploit synergistic effects of multiple fillers, leading to simultaneous improvements in piezoelectric output, flexibility, and durability. Such hybrid systems may also open avenues for multifunctional sensing, including pressure, strain, and temperature in a single platform.

- Scalable Manufacturing: Future work should focus on scaling lab-level fabrication techniques into cost-effective roll-to-roll processing[57], screen printing, and 3D printing. These scalable methods will ensure reproducibility, enable large-area e-skin production, and accelerate industrial adoption in robotics, healthcare, and consumer electronics.

- AI and IoT Integration: Embedding PVDF-based e-skin into IoT networks and pairing them with AI-driven analytics will allow predictive health monitoring, real-time adaptive calibration, and intelligent signal interpretation. Such integration will push e-skins beyond simple sensors toward fully autonomous smart interfaces for human-machine interaction.

- Healthcare Applications: PVDF nanocomposite e-skins hold promise in wound healing patches, prosthetic limb feedback systems, and drug delivery platforms. Clinical translation will require extensive biocompatibility validation, long-term reliability testing, and integration to wearable or implantable medical systems for real-world healthcare applications.

- Self-Healing and Sustainability: Incorporation of self-healing elastomers and biodegradable polymers will significantly extend device lifetimes[58] while addressing environmental concerns. Sustainable PVDF composites will reduce electronic waste and contribute to the development of eco-friendly, next-generation e-skins.

By addressing scalability, durability, and system integration challenges, future PVDF nanocomposite e-skins are expected to evolve from proof-of-concept devices to commercially viable smart interfaces that bridge biology and technology.

References

[1] L. Ruan, X. Yao, Y. Chang, L. Zhou, G. Qin, and X. Zhang, "Properties and applications of the β phase poly(vinylidene fluoride)," Polymers (Basel), vol. 10, no. 3, Feb. 2018, doi: 10.3390/POLYM10030228. View Article

[2] G. Wang, T. Liu, X. C. Sun, P. Li, Y. S. Xu, J. G. Hua, Y. H. Yu, S. X. Li, Y. Z. Dai, X. Y. Song, et al., "Flexible pressure sensor based on PVDF nanofiber," Sens Actuators A Phys, vol. 280, pp. 319-325, Sep. 2018, doi: 10.1016/J.SNA.2018.07.057. View Article

[3] K. Meng, X. Xiao, W. Wei, G. Chen, A. Nashalian, S. Shen, and J. Chen, "Wearable Pressure Sensors for Pulse Wave Monitoring," Advanced Materials, vol. 34, no. 21, May 2022, doi: 10.1002/ADMA.202109357. View Article

[4] W. Deng, Y. Zhou, A. Libanori, G. Chen, W. Yang, and J. Chen, "Piezoelectric nanogenerators for personalized healthcare," Chem Soc Rev, vol. 51, no. 9, pp. 3380-3435, Mar. 2022, doi: 10.1039/D1CS00858G. View Article

[5] A. Spanu, L. Pinna, F. Viola, L. Seminara, M. Valle, A. Bonfiglio, and P. Cosseddu, "A high-sensitivity tactile sensor based on piezoelectric polymer PVDF coupled to an ultra-low voltage organic transistor," Org Electron, vol. 36, pp. 57-60, Sep. 2016, doi: 10.1016/J.ORGEL.2016.05.034. View Article

[6] X. Yang, Y. Wang, and X. Qing, "A flexible capacitive sensor based on the electrospun PVDF nanofiber membrane with carbon nanotubes," Sens Actuators A Phys, vol. 299, p. 111579, Nov. 2019, doi: 10.1016/J.SNA.2019.111579. View Article

[7] Q. Zheng, J. hun Lee, X. Shen, X. Chen, and J. K. Kim, "Graphene-based wearable piezoresistive physical sensors," Materials Today, vol. 36, pp. 158-179, Jun. 2020, doi: 10.1016/j.mattod.2019.12.004. View Article

[8] R. Yin, D. Wang, S. Zhao, Z. Lou, and G. Shen, "Wearable Sensors-Enabled Human-Machine Interaction Systems: From Design to Application," Adv Funct Mater, vol. 31, no. 11, Mar. 2021, doi: 10.1002/ADFM.202008936. View Article

[9] C. R. Yang, M. F. Lin, C. K. Huang, W. C. Huang, S. F. Tseng, and H. H. Chiang, "Highly sensitive and wearable capacitive pressure sensors based on PVDF/BaTiO3 composite fibers on PDMS microcylindrical structures," Measurement, vol. 202, p. 111817, Oct. 2022, doi: 10.1016/J.MEASUREMENT.2022.111817. View Article

[10] M. S. Suen, Y. C. Lin, and R. Chen, "A flexible multifunctional tactile sensor using interlocked zinc oxide nanorod arrays for artificial electronic skin," Sens Actuators A Phys, vol. 269, pp. 574-584, Jan. 2018, doi: 10.1016/J.SNA.2017.11.053. View Article

[11] M. Zhu, Y. Wang, M. Lou, J. Yu, Z. Li, and B. Ding, "Bioinspired transparent and antibacterial electronic skin for sensitive tactile sensing," Nano Energy, vol. 81, p. 105669, Mar. 2021, doi: 10.1016/J.NANOEN.2020.105669. View Article

[12] Y. Zheng, T. Lin, N. Zhao, C. Huang, W. Chen, G. Xue, Y. Wang, C. Teng, X. Wang, and D. Zhou, "Highly sensitive electronic skin with a linear response based on the strategy of controlling the contact area," Nano Energy, vol. 85, p. 106013, Jul. 2021, doi: 10.1016/J.NANOEN.2021.106013. View Article

[13] J. Pan, W. Sun, X. Li, Y. Hao, Y. Bai, and D. Nan, "A noval transparent triboelectric nanogenerator as electronic skin for real-time breath monitoring," J Colloid Interface Sci, vol. 671, pp. 336-343, Oct. 2024, doi: 10.1016/J.JCIS.2024.05.127. View Article

[14] H. A. Alkabes, S. Elksass, K. E. El-Kelany, and M. El-Kemary, "A multifunctional wearable electronic skin: Wide range temperature sensing based on copper nanoclusters organo-hydrogel with self-healable, self-adhesive, anti-freezing properties," Sens Actuators A Phys, vol. 365, p. 114885, Jan. 2024, doi: 10.1016/J.SNA.2023.114885. View Article

[15] Y. Li, D. Jiang, Y. An, W. Chen, Z. Huang, and B. Jiang, "Wearable flexible pressure sensors: an intriguing design towards microstructural functionalization," J Mater Chem A Mater, vol. 12, no. 12, pp. 6826-6874, Dec. 2023, doi: 10.1039/D3TA05568J. View Article

[16] L. Liu, Y. Zhang, M. Wu, J. Zhang, L. Zhu, X. Zhou, and J. Xiong, "Asymmetric nanofiber photothermal interactive electronic skin with triboelectric autonomous thermal perceptivity," Nano Energy, vol. 127, p. 109717, Aug. 2024, doi: 10.1016/J.NANOEN.2024.109717. View Article

[17] S. R. Kim, S. Lee, and J. W. Park, "A skin-inspired, self-powered tactile sensor," Nano Energy, vol. 101, p. 107608, Oct. 2022, doi: 10.1016/J.NANOEN.2022.107608. View Article

[18] X. Yuan, X. Gao, X. Shen, J. Yang, Z. Li, and S. Dong, "A 3D-printed, alternatively tilt-polarized PVDF-TrFE polymer with enhanced piezoelectric effect for self-powered sensor application," Nano Energy, vol. 85, p. 105985, Jul. 2021, doi: 10.1016/J.NANOEN.2021.105985. View Article

[19] D. Zhao, W. Jia, X. Feng, H. Yang, Y. Xie, J. Shang, P. Wang, Y. Guo, and R. W. Li, "Flexible Sensors Based on Conductive Polymer Composites," Sensors, vol. 24, no. 14, Jul. 2024, doi: 10.3390/S24144664. View Article

[20] S. Zheng, H. Guo, F. Pan, F. Meng, H. Jiang, L. Ruan, J. Wang, Y. Gao, and W. Lu, "Breathable, durable, flexible, and battery-free full action response electronic textiles toward simply achieving the function of human skin," Nano Energy, vol. 122, p. 109292, Apr. 2024, doi: 10.1016/J.NANOEN.2024.109292. View Article

[21] H. Guan, D. Lv, T. Zhong, Y. Dai, L. Xing, X. Xue, Y. Zhang, and Y. Zhan, "Self-powered, wireless-control, neural-stimulating electronic skin for in vivo characterization of synaptic plasticity," Nano Energy, vol. 67, p. 104182, Jan. 2020, doi: 10.1016/J.NANOEN.2019.104182. View Article

[22] H. Dong, L. Zhang, T. Wu, H. Song, J. Luo, F. Huang, and C. Zuo, "Flexible pressure sensor with high sensitivity and fast response for electronic skin using near-field electrohydrodynamic direct writing," Org Electron, vol. 89, p. 106044, Feb. 2021, doi: 10.1016/J.ORGEL.2020.106044. View Article

[23] M. Asaduzzaman, A. A. Samad, O. Faruk, M. S. Reza, S. Lim, Z. Islam, Y. Lee, D. Kim, and J. Y. Park, "TiO2 nanoparticles-decorated MXene-PVDF composite carbon nanofibrous mats-based free-standing electrodes for flexible and breathable microsupercapacitors," Carbon N Y, vol. 241, p. 120381, Jun. 2025, doi: 10.1016/J.CARBON.2025.120381. View Article

[24] J. Chen, L. Guan, M. Xu, T. Hu, Z. Pang, D. Shi, and W. Wang, "Ultra-sensitive, fast response microcapsule structure capacitive sensor with encapsulated columnar nano-ZnO for electronic skin," J Alloys Compd, vol. 1010, p. 178245, Jan. 2025, doi: 10.1016/J.JALLCOM.2024.178245. View Article

[25] Y. Wu, Y. Ma, H. Zheng, and S. Ramakrishna, "Piezoelectric materials for flexible and wearable electronics: A review," Mater Des, vol. 211, Dec. 2021, doi: 10.1016/j.matdes.2021.110164. View Article

[26] J. Wang, J. Jiang, C. Zhang, M. Sun, S. Han, R. Zhang, N. Liang, D. Sun, and H. Liu, "Energy-efficient, fully flexible, high-performance tactile sensor based on piezotronic effect: Piezoelectric signal amplified with organic field-effect transistors," Nano Energy, vol. 76, p. 105050, Oct. 2020, doi: 10.1016/J.NANOEN.2020.105050. View Article

[27] K. Guo, S. Gao, Y. Li, J. Yin, W. Yue, S. Zhao, C. Zhang, J. Liu, S. Li, S. Wu, et al., "A P(VDF-TrFE) nanofiber composites based multilayer structured dual-functional flexible sensor for advanced pressure-humidity sensing," Chemical Engineering Journal, vol. 461, p. 141970, Apr. 2023, doi: 10.1016/J.CEJ.2023.141970. View Article

[28] J. Luo, L. Zhang, T. Wu, H. Song, and C. Tang, "Flexible piezoelectric pressure sensor with high sensitivity for electronic skin using near-field electrohydrodynamic direct-writing method," Extreme Mech Lett, vol. 48, p. 101279, Oct. 2021, doi: 10.1016/J.EML.2021.101279. View Article

[29] N. Turdakyn, A. Medeubayev, I. Abay, D. Adair, and G. Kalimuldina, "Preparation of a piezoelectric PVDF sensor via electrospinning," Mater Today Proc, vol. 49, pp. 2478-2481, Jan. 2022, doi: 10.1016/J.MATPR.2020.11.914. View Article

[30] W. Deng, Y. Zhou, A. Libanori, G. Chen, W. Yang, and J. Chen, "Piezoelectric nanogenerators for personalized healthcare," Chem Soc Rev, vol. 51, no. 9, pp. 3380-3435, Mar. 2022, doi: 10.1039/D1CS00858G. View Article

[31] J. Yu, X. Hou, J. He, M. Cui, C. Wang, W. Geng, J. Mu, B. Han, and X. Chou, "Ultra-flexible and high-sensitive triboelectric nanogenerator as electronic skin for self-powered human physiological signal monitoring," Nano Energy, vol. 69, p. 104437, Mar. 2020, doi: 10.1016/J.NANOEN.2019.104437. View Article

[32] Y. Cheng, W. Zhu, X. Lu, and C. Wang, "Mechanically robust, stretchable, autonomously adhesive, and environmentally tolerant triboelectric electronic skin for self-powered healthcare monitoring and tactile sensing," Nano Energy, vol. 102, p. 107636, Nov. 2022, doi: 10.1016/J.NANOEN.2022.107636. View Article

[33] S. Wu, Y. Zhao, J. Wang, X. Zhao, W. Zhai, X. Zhu, P. Wan, M. Cui, L. Gao, K. Dai, et al., "All-nanofiber self-powered electronic skin with electrospinning humidity-controlled structure for human muscle detection during fitness," Composites Communications, vol. 57, p. 102421, Aug. 2025, doi: 10.1016/J.COCO.2025.102421. View Article

[34] M. Zhu, M. Lou, I. Abdalla, J. Yu, Z. Li, and B. Ding, "Highly shape adaptive fiber based electronic skin for sensitive joint motion monitoring and tactile sensing," Nano Energy, vol. 69, p. 104429, Mar. 2020, doi: 10.1016/J.NANOEN.2019.104429. View Article

[35] J. H. Lee, K. Cho, and J. K. Kim, "Age of Flexible Electronics: Emerging Trends in Soft Multifunctional Sensors," Advanced Materials, vol. 36, no. 16, Apr. 2024, doi: 10.1002/ADMA.202310505. View Article

[36] J. Liu, L. Zhang, N. Wang, H. Zhao, and C. Li, "Nanofiber-reinforced transparent, tough, and self-healing substrate for an electronic skin with damage detection and program-controlled autonomic repair," Nano Energy, vol. 96, p. 107108, Jun. 2022, doi: 10.1016/J.NANOEN.2022.107108. View Article

[37] T. Sekine, K. Ito, Y. Shouji, R. Suga, T. Yasuda, Y. F. Wang, Y. Takeda, D. Kumaki, F. D. Dos Santos, H. Tong, et al., "Robotic e-skin for high performance stretchable acceleration sensor via combinations of novel soft and functional polymers," Appl Mater Today, vol. 33, p. 101877, Aug. 2023, doi: 10.1016/J.APMT.2023.101877. View Article

[38] C. Zhang, S. Liu, X. Huang, W. Guo, Y. Li, and H. Wu, "A stretchable dual-mode sensor array for multifunctional robotic electronic skin," Nano Energy, vol. 62, pp. 164-170, Aug. 2019, doi: 10.1016/J.NANOEN.2019.05.046. View Article

[39] Y. Wang, M. Zhu, X. Wei, J. Yu, Z. Li, and B. Ding, "A dual-mode electronic skin textile for pressure and temperature sensing," Chemical Engineering Journal, vol. 425, Dec. 2021, doi: 10.1016/j.cej.2021.130599. View Article

[40] Y. Song, W. Sun, X. Shi, Z. Qin, Q. Wu, S. Yin, S. Liang, Z. Liu, and H. Sun, "Bio-inspired e-skin with integrated antifouling and comfortable wearing for self-powered motion monitoring and ultra-long-range human-machine interaction," J Colloid Interface Sci, vol. 679, pp. 1299-1310, Feb. 2025, doi: 10.1016/J.JCIS.2024.10.056. View Article

[41] M. Zhu, M. Lou, J. Yu, Z. Li, and B. Ding, "Energy autonomous hybrid electronic skin with multi-modal sensing capabilities," Nano Energy, vol. 78, p. 105208, Dec. 2020, doi: 10.1016/J.NANOEN.2020.105208. View Article

[42] J. W. Park and J. Jang, "Fabrication of graphene/free-standing nanofibrillar PEDOT/P(VDF-HFP) hybrid device for wearable and sensitive electronic skin application," Carbon N Y, vol. 87, no. C, pp. 275-281, Jun. 2015, doi: 10.1016/J.CARBON.2015.02.039. View Article

[43] H. He, Y. Fu, W. Zang, Q. Wang, L. Xing, Y. Zhang, and X. Xue, "A flexible self-powered T-ZnO/PVDF/fabric electronic-skin with multi-functions of tactile-perception, atmosphere-detection and self-clean," Nano Energy, vol. 31, pp. 37-48, Jan. 2017, doi: 10.1016/J.NANOEN.2016.11.020. View Article

[44] J. Luo, L. Zhang, T. Wu, H. Song, C. Tang, F. Huang, and C. Zuo, "Flexible electronic skin with high performance pressure sensing based on PVDF/rGO/BaTiO3 composite thin film," Org Electron, vol. 98, p. 106296, Nov. 2021, doi: 10.1016/J.ORGEL.2021.106296. View Article

[45] O. Yue, X. Wang, M. Hou, M. Zheng, Z. Bai, B. Cui, S. Cha, and X. Liu, "Skin-inspired wearable self-powered electronic skin with tunable sensitivity for real-time monitoring of sleep quality," Nano Energy, vol. 91, p. 106682, Jan. 2022, doi: 10.1016/J.NANOEN.2021.106682. View Article

[46] B. Mahanty, K. Maity, S. Sarkar, and D. Mandal, "Human Skin Interactive Self-powered Piezoelectric e-skin Based on PVDF/MWCNT Electrospun Nanofibers for Non-invasive Health Care Monitoring," Mater Today Proc, vol. 21, pp. 1964-1968, Jan. 2020, doi: 10.1016/J.MATPR.2020.01.282. View Article

[47] C. Dong, Y. Fu, W. Zang, H. He, L. Xing, and X. Xue, "Self-powering/self-cleaning electronic-skin basing on PVDF/TiO2 nanofibers for actively detecting body motion and degrading organic pollutants," Appl Surf Sci, vol. 416, pp. 424-431, Sep. 2017, doi: 10.1016/J.APSUSC.2017.04.188. View Article

[48] L. Lu, W. Ding, J. Liu, and B. Yang, "Flexible PVDF based piezoelectric nanogenerators," Nano Energy, vol. 78, Dec. 2020, doi: 10.1016/j.nanoen.2020.105251. View Article

[49] S. Veeralingam and S. Badhulika, "Low-density, stretchable, adhesive PVDF-polypyrrole reinforced gelatin based organohydrogel for UV photodetection, tactile and strain sensing applications," Mater Res Bull, vol. 150, p. 111779, Jun. 2022, doi: 10.1016/J.MATERRESBULL.2022.111779. View Article

[50] J. Luo, L. Zhang, T. Wu, H. Song, and C. Tang, "Flexible piezoelectric pressure sensor with high sensitivity for electronic skin using near-field electrohydrodynamic direct-writing method," Extreme Mech Lett, vol. 48, Oct. 2021, doi: 10.1016/j.eml.2021.101279. View Article

[51] T. Yang, H. Pan, G. Tian, B. Zhang, D. Xiong, Y. Gao, C. Yan, X. Chu, N. Chen, S. Zhong, et al., "Hierarchically structured PVDF/ZnO core-shell nanofibers for self-powered physiological monitoring electronics," Nano Energy, vol. 72, p. 104706, Jun. 2020, doi: 10.1016/J.NANOEN.2020.104706. View Article

[52] Z. Lou, S. Chen, L. Wang, R. Shi, L. Li, K. Jiang, D. Chen, and G. Shen, "Ultrasensitive and ultraflexible e-skins with dual functionalities for wearable electronics," Nano Energy, vol. 38, pp. 28-35, Aug. 2017, doi: 10.1016/J.NANOEN.2017.05.024. View Article

[53] F. Yuan, W. Wang, S. Liu, J. Zhou, S. Wang, Y. Wang, H. Deng, S. Xuan, and X. Gong, "A self-powered three-dimensional integrated e-skin for multiple stimuli recognition," Chemical Engineering Journal, vol. 451, p. 138522, Jan. 2023, doi: 10.1016/J.CEJ.2022.138522. View Article

[54] J. Zhang, J. Guo, K. Guo, Q. Li, S. Yan, T. Li, and B. Xin, "Multifunctional nanofiber-based electronic skin with moisture-wicking, piezoelectric motion sensing and thermochromic temperature response," J Colloid Interface Sci, vol. 701, p. 138773, Jan. 2026, doi: 10.1016/J.JCIS.2025.138773. View Article

[55] Y. Ai, Z. Lou, S. Chen, D. Chen, Z. M. Wang, K. Jiang, and G. Shen, "All rGO-on-PVDF-nanofibers based self-powered electronic skins," Nano Energy, vol. 35, pp. 121-127, May 2017, doi: 10.1016/J.NANOEN.2017.03.039. View Article

[56] M. Zhu, J. Li, J. Yu, Z. Li, and B. Ding, "Superstable and Intrinsically Self-Healing Fibrous Membrane with Bionic Confined Protective Structure for Breathable Electronic Skin," Angewandte Chemie - International Edition, vol. 61, no. 22, May 2022, doi: 10.1002/ANIE.202200226. View Article

[57] Z. Mei, F. Wang, Y. Liu, K. Liao, S. Ma, Q. Shen, S. Zhang, H. Wang, and L. Wang, "Advances in carbon nanomaterial-based triboelectric wearable devices for human health monitoring," Chemical Engineering Journal, vol. 500, Nov. 2024, doi: 10.1016/j.cej.2024.157423. View Article

[58] S. Wang, H. Q. Shao, Y. Liu, C. Y. Tang, X. Zhao, K. Ke, R. Y. Bao, M. B. Yang, and W. Yang, "Boosting piezoelectric response of PVDF-TrFE via MXene for self-powered linear pressure sensor," Compos Sci Technol, vol. 202, p. 108600, Jan. 2021, doi: 10.1016/J.COMPSCITECH.2020.108600. View Article